The pianos’s massive plate frame – sometimes referred to as the “harp”, is made of cast iron. The casting of a piano’s plate is a delicate science and art, since the dimensions are crucial and the iron shrinks by about one percent during cooling.

The strings of a piano individually have from 150 to 200 pounds of tension, and the cumulative forces acting on a piano can be anywhere from 20,000 to 40,000 pounds.

The piano is a stringed instrument. Its many parts are organized into five general structural and mechanical areas of either grand or vertical pianos.

These are: the case of the wing-shaped grand piano (or the cabinet of the vertical or upright piano); the soundboard and the ribs and bridges that are its components; the cast iron plate; the strings; and, collectively, the keys, hammers, and piano action or mechanism.

The case has many structural parts for attaching legs and tuning pins, but perhaps the rim and the keybed or shelf where the keys and piano action will be installed are most important.

The soundboard amplifies the vibrations of the strings, which are transmitted through bridges. The cast iron plate is installed over the soundboard and pinblock (part of the case), and it provides the strength to anchor the strings under tension.

Nose bolts and perimeter bolts anchor the plate to the braces and inner rim of the case. The 220 to 240 strings of the piano are attached to hitch pins along the curved edge of the cast iron plate and to tuning pins across the front of the piano, roughly parallel to the keyboard.

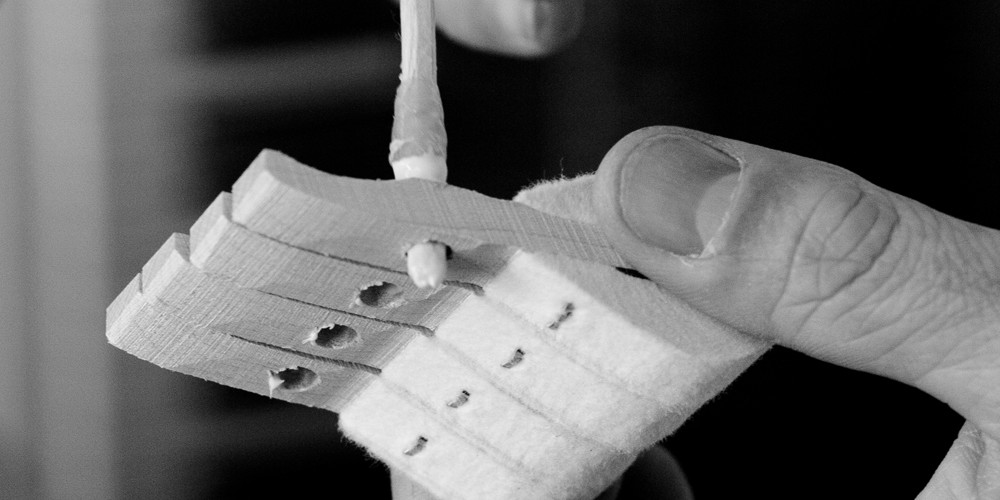

Much work is executed after its casting creation including drilling, sanding, sealing, agraffe installation and the customary as its final treatment.